The only product you need for inexpensive, dynamic multi-point instrument calibration

Problem: Low level (ppm Level) gas calibration standards are quite expensive, especially with reactive compounds (sulfurs, oxygenates, halogenated compounds, etc.)

The Dynamic Blender allows for cheaper standards with higher concentrations to be blended down to low levels.

Problem: Multi point calibration requires the use of multiple standards with varying concentrations.

The Dynamic Blender allows for multi-point calibration with the use of a single standard that can be diluted down to lower concentrations.

Problem: Standards that have low level reactive compounds expire relatively quickly causing the user to constantly purchase new valid standards.

The dynamic blender allows the user to blend down the high concentration standard to low levels for calibration which eliminates the need to purchase expensive standards with low level reactive compounds. The high concentration standards last longer, reducing the frequency of purchasing new gas standards.

Problem: Some detectors require multi-point calibration due to nonlinear response curves

Some GC detectors such as FPDs, PFPDs, and NPDs have nonlinear response curves and require multi-point calibration as a result. The dynamic blender makes any lab have the capability of multi-point calibration opening the doors to new GC detectors and applications.

Problem: Some systems lose their linear response at low levels

Some systems may have issues with certain components at low levels due to a number of things (reactivity, absorption onto active sites in the flow path, poor sensitivity due to sample size or split ratio, etc.). If the system cannot maintain linearity at low level concentrations it would be very hard to determine with every day use causing the lab to report inaccurate numbers. The Dynamic blender allows the user to test linearity throughout the range of concentrations they see in their samples.

We at Wasson have decades of GC experience offering our customers turnkey solutions, often on the cutting edge of GC technology. We often use dynamic blenders in our GC application test lab to validate lower detection limits, linear dynamic ranges, and for calibration of non-linear detector systems. Having a Dynamic blender or two around has proven to be very helpful in increasing the productivity and capability of our GC lab.

- Inert flow path

- Heated bridge to GC to prevent sample condensation

- MFC can control from 0-500 cc/m allowing for a wide range of dilutions

- Compatible with any GC configured with a gas sampling valve

- MFC for automatic and rapid diluent gas control

- Mass flow control range: 0-500 cc/min

- Maximum temperature: 150°C

- Maximum diluent pressure: 100 psig

- Passivated sample tubing for reactive components

- Compatible with any GC configured with a gas sampling valve

- Heated bridge precisely controlled by built in Watlow controller

Application 1:

Multi point calibration of FPD systems analyzing ppm level sulfurs

Application 2:

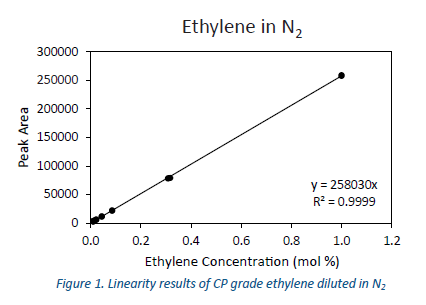

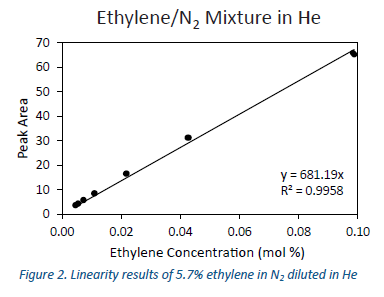

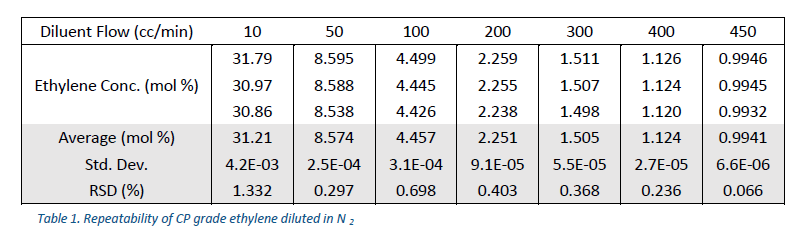

Linearity testing per as required by certain standardized methods

The dynamic blender can be used be setup for use in a single location or can be moved around as needed with relatively little setup required. For the Dynamic blender to operate a cylinder of diluent gas must be attached to the Dynamic Blender with some sort of transfer line. The sample or standard to be diluted must be attached to the sample inlet of the dynamic blender with a transfer line. Power supply from a wall outlet is needed to operate the electronic MFC. The heated bridge must be attached to the gas sample inelt of the GC. With this very minimal setup the Dynamic blender can be used for various applications as described in the “Need” section.

Theory of use:

The concentration of the mixture is a function of the flow rate of the sample as well as that of the diluent gas. The sample flow and diluent flow are controlled by adjusting the pressure of the supply. The diluent gas flow is also finely controlled by the digital mass flow controller at the front of the blender. By adjusting the flow rate of the gases, and by measuring the flow rate at the blender outlet, the final concentration of the sample can be calculated. The blender is designed to produce a final concentration up to four orders of magnitude lower than the initial concentration.

In the gas phase, the concentration of your final mixture is a function of the flow rates of the sample and the diluent gas as follows:

C2 = [M1/M2]*C1

Where C2 = final concentration of mixture

M1 = flow rate of sample gas only

M2 = total flow rate of diluent gas plus sample gas

C1 = original concentration of sample gas

Using the desired final concentration (C2), the following calculation is performed to determine the total flow rate of diluent gas plus sample gas (M2) needed:

M2 = [M1*C1]/C2

The sample flow rate (M1) will be determined by your flow-measuring device. The accuracy of the final concentration is directly related to the accuracy of the flow measurement. The sample flow rate can be adjusted by changing the inlet pressure of the sample.

Application 3:

Low level calibration on reactive compounds that are not available from gas standard vendors

- NSS Laboratories Product evaluation (model 1107)

- EU Declaration of Conformity

- MFC for automatic and rapid diluent gas control

- Mass flow control range: 0-500 cc/min

- Maximum temperature: 150°C

- Maximum diluent pressure: 100 psig

- Passivated sample tubing for reactive components

- Compatible with any GC configured with a gas sampling valve

- Heated bridge precisely controlled by built in Watlow controller

- Pre-Programmed Diluent Gases: Approx. 100 pure gases and mixtures

- Customizable Diluent Gases: 20 user configurable mixture slots

- Working Dilution Range: >2 orders of magnitude

- Maximum Diluent Pressure: 100 psi (leak tested to this pressure)

- Maximum Temperature: 150°C (operation verified at this temp.)

- MFC Range: 10 – 500 cc/min

- Fittings: 1/8” Swagelok™: vent and diluent inlet, 1/16”

- Swagelok™: sample inlet

- Filters: 7 μm in-line gas filters (treated)

- Sample Surface Treatment: Sulfinert® treated for trace reactive compounds (sulfurs, oxygenates, etc.)*

- Electrical Requirements: 120/240VAC (user defined)

- Dimensions: 3.6” H x 8.7” D x 9.4” W / 9.2 cm H x 22.1 cm D x 23.9 cm W

- Weight: 14.5 lbs. / 6.6 kg

- Sample gas and/or calibration gas

- Diluent gas (max pressure 100 psi)

- Standard wall outlet

- Flowmeter

- Maximum diluent gas supply pressure 100 psi

- GC with Gas Sample Valve

Lab Devices Brochure

Wasson-ECE Instrumentation

101 Rome Ct., Fort Collins, Colorado USA 80524

Phone: +1 (970) 221-9179

Fax: +1 (970) 221-9364

© 2026. All Rights Reserved.

When you can't afford to be wrong. TM